breaking news

We like to share our knowledge. In this section we will share the things that are of interest to you.

From single-use to multi-use: the new DSPLY!

Everyone knows them: the cardboard displays in supermarkets showcasing seasonal items or new products. After the action, these displays disappear into the paper press to be reused. But those displays can never be recycled into new displays, at most into packaging material, note paper or toilet paper. This could be a lot more sustainable, so: enter Hollarts! Read about our sustainable DSPLY here.

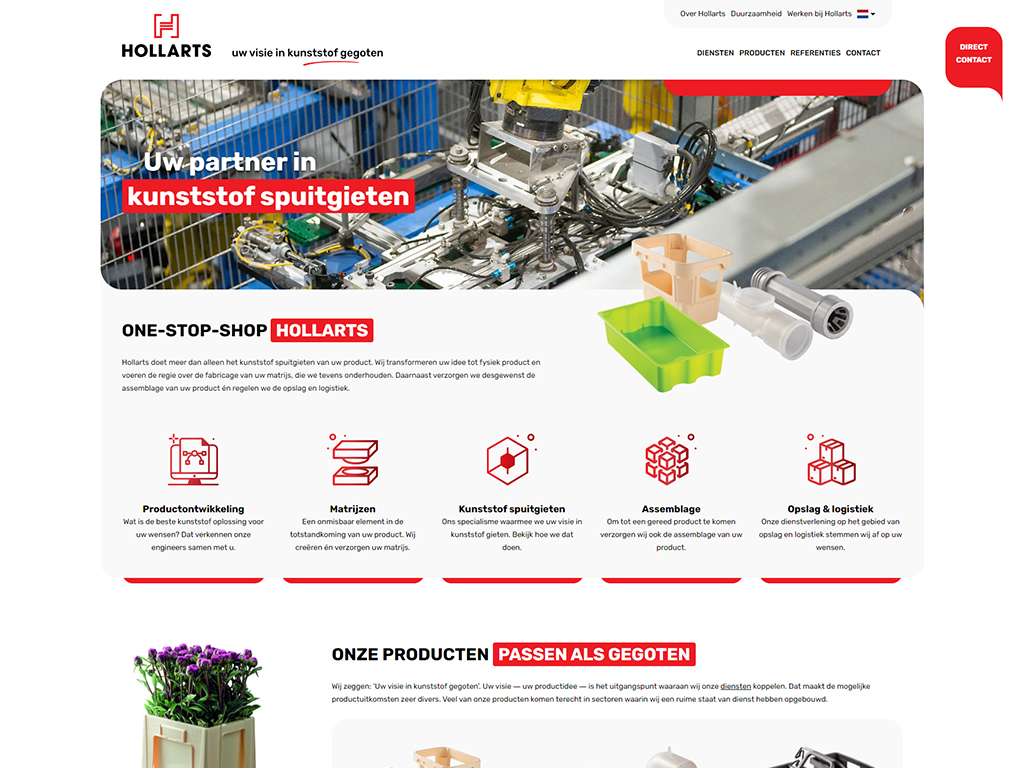

New Hollarts website

We proudly present our new website. It didn't just come out of nowhere, by the way. After all, we started redefining our company. Who are we, what do we do and why do we do that? Of course we know that, but sometimes it helps to formulate it sharply again. Purely to keep Hollarts firmly anchored in the market. A kind of repositioning, say.

Graduated in Injection Moulding II

Plastic injection moulding is a profession. But it is a profession that is in motion due to rapid technological developments. This also means that our professionals are constantly developing. This year, all our machine counters, operators and senior operators followed and successfully completed the Injection Moulding II training.